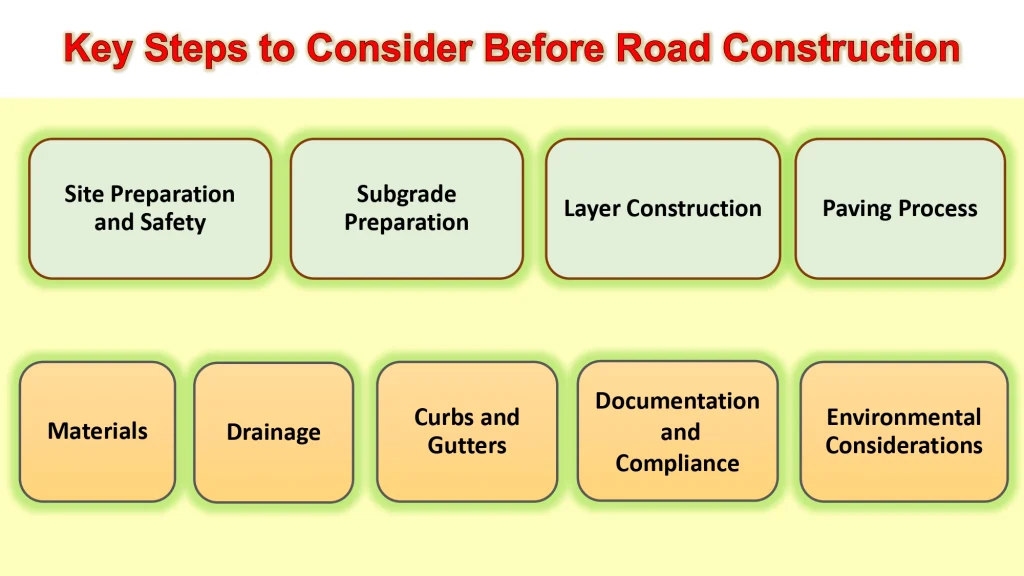

Road construction is a complex and challenging task, especially for fresh engineers who often face difficulties due to a lack of experience. In this article, I will explore some of the critical aspects of road construction, such as Materials Selection, Drainage, Curbs and Gutters, Documentation, and Environmental Considerations. These elements are essential for creating durable, safe, and environmentally-friendly roadways. If you missed it, I’ve already discussed other vital components like Site Preparation, Subgrade Preparation, Layer construction, and the Paving Process in a previous article. Together, these insights aim to equip you with the knowledge needed to tackle the various challenges you may encounter in road construction.

Contents

1. Materials

The materials used in road construction are crucial for building a durable, safe, and long-lasting roadway. Each material has specific properties that contribute to the overall performance of the road. Here’s a brief overview of the key materials used:

1.1. Soil

Soil mainly provides foundation and support.

– Foundation: Forms the subgrade, the foundation layer of the road.

– Support: Provides support for all other layers of the road structure.

Types:

– Clay, Silt, Sand, Gravel: Different types of soils are used based on their properties and the requirements of the project.

Actions:

– Testing: Perform soil tests to determine its suitability and necessary treatments for compaction and stability.

1.2. Aggregates

Aggregates mainly provide strength and drainage

– Strength: Provide structural strength and stability to the road layers.

– Drainage: Facilitate proper drainage and reduce water retention in the pavement structure.

Types:

– Crushed Stone: Used for the base and sub-base layers.

– Gravel and Sand: Used in various layers for different purposes, including drainage and load distribution.

Actions:

– Quality Control: Ensure aggregates meet specified size, shape, and durability requirements through sieve analysis and other tests. (Read more about Gradation Curves)

1.3. Bitumen

Bitumen is required to bind the aggregates and provide protection for underlying layers.

– Binding Agent: Binds aggregates together in asphalt mixes, providing flexibility and durability to the road surface.

– Waterproofing: Prevents water infiltration, protecting the underlying layers from moisture damage.

Types:

– Penetration Grade Bitumen, Modified Bitumen: Selected based on climate conditions and specific performance requirements.

Actions

– Temperature Control: Maintain proper temperatures during mixing and laying to ensure optimal performance of the bitumen.

1.4. Hot Mix Asphalt (HMA)

Hot Mix Asphalt (HMA) is to provide a surface layer and eventually distributes the load.

– Surface Layer: Provides a smooth, durable, and flexible surface for vehicles.

– Load Distribution: Helps distribute traffic loads to the underlying layers.

Components:

– Aggregates and Bitumen: Mixed at high temperatures to create a cohesive material.

Actions

– Mix Design: Design the mix to meet specific performance criteria, including stability, durability, and resistance to deformation. (Read more about Asphalt Mix Design)

1.5. Portland Cement Concrete

Portland Cement Concrete is to provide a durable surface.

– Pavement Surface: Used in rigid pavement construction, providing a strong, durable surface.

– Curbs and Gutters: Used for constructing curbs, gutters, and other structures requiring high strength.

Components:

– Cement, Aggregates, Water, Admixtures: Mixed to form concrete with desired properties

Actions

– Mixing and Curing: Ensure proper mixing and curing techniques to achieve the required strength and durability.

1.6. Geotextiles

Geotextiles is to provide additional strength and enhance drainage:

– Separation: Prevents mixing of different soil layers.

– Reinforcement: Provides additional strength to soil and aggregate layers.

– Drainage: Enhances drainage by allowing water to pass while retaining soil particles.

Types:

– Woven and Non-woven Geotextiles: Selected based on the specific needs of the project.

Actions

– Installation: Properly place geotextiles to ensure they function as intended

1.7. Additives and Stabilizers

The purpose of additives and stabilizers is to enhance soil properties and load-bearing capacities.

– Improved Performance: Enhance the properties of soil, aggregates, or asphalt.

– Stabilization: Increase the load-bearing capacity and durability of weak soils or materials.

Types:

– Lime, Cement, Fly Ash, Polymers: Used for soil stabilization and asphalt modification.

Actions

– Application: Apply and mix additives according to specified proportions and techniques to achieve the desired improvements

Materials in road construction include soil, aggregates, bitumen, hot mix asphalt, Portland cement concrete, geotextiles, and various additives and stabilizers. Each material plays a specific role in the construction process, contributing to the road’s overall strength, durability, and performance. Proper selection, testing, and application of these materials are essential for building a high-quality roadway.

2. Drainage

Proper drainage is vital in road construction to ensure the longevity and safety of the roadway. Effective drainage systems prevent water accumulation, which can cause various issues such as pavement deterioration, erosion, and reduced safety for road users.

2.1. Surface Drainage

The purpose of surface drainage is to manage the water runoff.

– Water Runoff Management: Directs rainwater and surface runoff away from the road surface to prevent water pooling and hydroplaning.

Components:

– Camber and Slope: The road surface is designed with a slight slope (camber) to facilitate water flow towards the edges.

– Curbs and Gutters: Curbs guide water into gutters, which channel it towards drainage inlets or catch basins.

Actions

– Design: Ensure the road has the appropriate camber and slopes to direct water efficiently.

– Installation: Properly install curbs and gutters to effectively capture and direct runoff.

2.2. Subsurface Drainage

The purpose of subsurface drainage is to manage the Water Table Management.

– Water Table Management: Removes water from beneath the road surface to prevent weakening of the subgrade and base layers, which can lead to pavement failure

Components:

– Drainage Layers: Use permeable materials like sand and gravel to create a drainage layer that facilitates water movement away from the road base.

– Subsurface Drains: Install perforated pipes or French drains to collect and transport groundwater away from the road structure.

Actions

– Assessment: Conduct a thorough assessment of soil and water table conditions to design an effective subsurface drainage system.

– Installation: Properly install drainage layers and subsurface drains to ensure efficient water removal.

2.3. Inspection and Maintenance of Drainage

Regular Inspections:

– Monitoring: Regularly inspect drainage systems to ensure they are functioning correctly and free of blockages or damage.

– Maintenance: Perform routine maintenance, such as clearing debris from gutters, ditches, and culverts, and repairing any damaged components.

Seasonal Considerations:

– Pre-Winter Checks: Inspect and clean drainage systems before winter to prevent ice buildup and blockages.

– Post-Storm Inspections: Check drainage systems after heavy rain or storms to ensure they are working effectively and address any issues immediately.

Effective drainage systems are crucial for maintaining the integrity and safety of roadways. Proper design, installation, and maintenance of surface and subsurface drainage structures ensure efficient water management, preventing damage to the road and surrounding environment. Regular inspections and maintenance are essential to keep the drainage systems functioning optimally.

3. Curbs and Gutters

Curbs are vertical or sloped barriers that delineate the edge of the pavement, providing a channel for water flow while the Gutters are shallow channels positioned alongside curbs to collect and convey runoff water to drainage inlets.

Curbs and gutters are essential components in road construction, serving both functional and aesthetic purposes.

– Direct surface water to drainage systems

– Preventing water from pooling on the roadway and reducing the risk of hydroplaning and pavement damage.

– Effective drainage minimizes erosion along the road edges.

– Well-aligned curbs and gutters enhance the visual appeal of the roadway

3.1. Types of Curbs

– Barrier Curbs: Tall, vertical curbs designed to prevent vehicles from leaving the roadway.

– Mountable Curbs: Lower, sloped curbs that allow vehicles to cross over them easily, typically used in residential areas.

Action:

– Compaction: Compact the subgrade to achieve the desired density and strength.

– Moisture Control: Ensure proper moisture content to facilitate compaction and prevent future instability.

3.2. Inspection and Maintenance of Curbs & Gutters

Regular Checks:

– Post-Construction Inspection: Conduct thorough inspections after installation to ensure alignment, level, and quality meet project specifications.

– Ongoing Maintenance: Regularly inspect and maintain curbs and gutters to address any damage or wear, ensuring continued effectiveness in water management and road safety.

Curbs and gutters are critical for effective drainage, road safety, and aesthetics in road construction. Ensuring proper alignment, quality concrete, and precise construction techniques are key to their successful implementation. Regular inspections and maintenance help sustain their functionality and longevity.

4. Documentation and Compliance

Proper documentation and compliance with regulations are essential for ensuring quality, safety, and legal adherence in road construction projects. Proper documentation can help the project authority in times of legal action. Here are the key aspects to consider:

4.1. Project Plans and Specifications

Guidelines: Serve as detailed guides for construction activities, specifying materials, methods, and quality standards.

Compliance: Ensure that all construction work aligns with the project’s design and regulatory requirements.

Actions:

Frequently consult project plans and specifications to verify that ongoing work meets the outlined criteria.

4.2. Quality Control Records

Verification: Provide evidence that construction processes and materials meet specified standards.

Traceability: Allow tracking of material sources, test results, and compliance with quality standards.

Components:

Material Test Reports:

Document results of tests conducted on construction materials (e.g.,

aggregates, asphalt).

Compaction Records: Include results of field density tests and compaction efforts.

Inspection Logs: Keep detailed logs of inspections conducted at various stages of the project.

4.3. Record

Keeping

Documentation: Keep detailed records of all construction activities, changes, and decisions.

Accessibility: Ensure that records are easily accessible for review by project stakeholders and regulatory authorities.

Components:

Daily Logs: Document daily activities, weather conditions, and progress.

Change Orders: Record any changes to the project scope, design, or materials, along with justifications and approvals.

4.4. Health and Safety Compliance

Worker Safety: Protect the health and safety of workers and the public.

Standards:

– Safety Protocols: Implement and document adherence to safety protocols, including PPE usage, safety training, and emergency preparedness.

– Incident Reports: Maintain records of any incidents or accidents, including investigations and corrective actions taken.

Documentation and compliance considerations in road construction involve maintaining detailed project plans and specifications, keeping comprehensive quality control records, ensuring regulatory compliance, adhering to environmental and health and safety standards, and thorough record keeping. These practices are essential for project success, legal adherence, and overall quality assurance.

5. Environmental Considerations

Ensuring environmental protection during road construction is crucial for minimizing the impact on the surrounding ecosystem and complying with regulations. Here are key aspects to consider:

5.1. Erosion Control

– Silt Fences and Barriers: Install silt fences and other barriers to prevent soil erosion and sediment runoff into nearby water bodies.

– Vegetation: Use temporary or permanent vegetation to stabilize exposed soil and reduce erosion.

– Mulching and Matting: Apply mulch or erosion control mats on slopes and disturbed areas to protect the soil.

5.2. Pollution Prevention

– Waste Management: Properly handle and dispose of construction waste, including hazardous materials like oil, fuel, and chemicals, to prevent soil and water contamination.

– Spill Containment: Have spill containment plans and equipment on-site to quickly address any accidental spills of harmful substances.

– Dust Control: Implement dust control measures, such as watering down construction areas or using dust suppressants, to minimize air pollution.

5.3. Water Management

– Stormwater Management: Design and implement effective stormwater management systems to control runoff, prevent flooding, and reduce water pollution.

– Drainage Systems: Ensure proper design and installation of drainage systems like culverts and ditches to manage surface and subsurface water flow, reducing the risk of erosion and waterlogging.

5.4. Noise and Vibration Control

– Equipment Maintenance: Use well-maintained, low-noise equipment to minimize noise pollution.

– Operation Scheduling: Schedule construction activities to limit noise during sensitive times of the day, particularly in residential areas.

5.5. Habitat Protection

– Wildlife Considerations: Identify and protect local wildlife habitats and migration routes. Implement measures to avoid disturbing nesting or breeding areas.

– Vegetation Preservation: Preserve existing trees and vegetation where possible, and plan for replanting or landscaping after construction is completed

Environmental considerations in road construction include erosion control, pollution prevention, water management, noise and vibration control, habitat protection, and regulatory compliance. Implementing these measures helps minimize the environmental impact of construction activities, ensuring a balance between infrastructure development and environmental preservation.

This article has covered key topics such as materials, drainage, curbs and gutters, documentation, and environmental considerations— each playing a crucial role in ensuring the success and sustainability of road construction projects. I hope these insights help you better understand and manage these aspects effectively. If you haven’t already, be sure to check out the previous article, where I discussed the foundational stages of site preparation, subgrade preparation, layer construction, and the paving process. Together, these articles will provide a comprehensive guide to help you navigate the complexities of road construction with greater confidence.