Pavement engineering is a critical field within civil engineering, focusing on the design, construction, and maintenance of roadways and other paved surfaces. The effectiveness and longevity of these surfaces hinge on a solid understanding of the principles governing pavement design and the materials used in their construction. This article describes the essential principles of pavement engineering, exploring the methodologies that ensure durability and performance. Additionally, it provides a comprehensive guide to the various materials employed in pavement construction, from traditional asphalt and concrete to innovative, sustainable alternatives. Whether you are a seasoned engineer or a newcomer, this article offers valuable insights into the complex interplay between design principles and material selection in creating resilient and enduring pavements.

Contents

A. Pavement Materials

Pavement materials are categorized into different layers: the surface layer, base layer, subbase layer, and subgrade. The common materials used in each layer are describe below.

A.1. Surface Layer Materials

A.1.1. Asphalt (Bituminous)

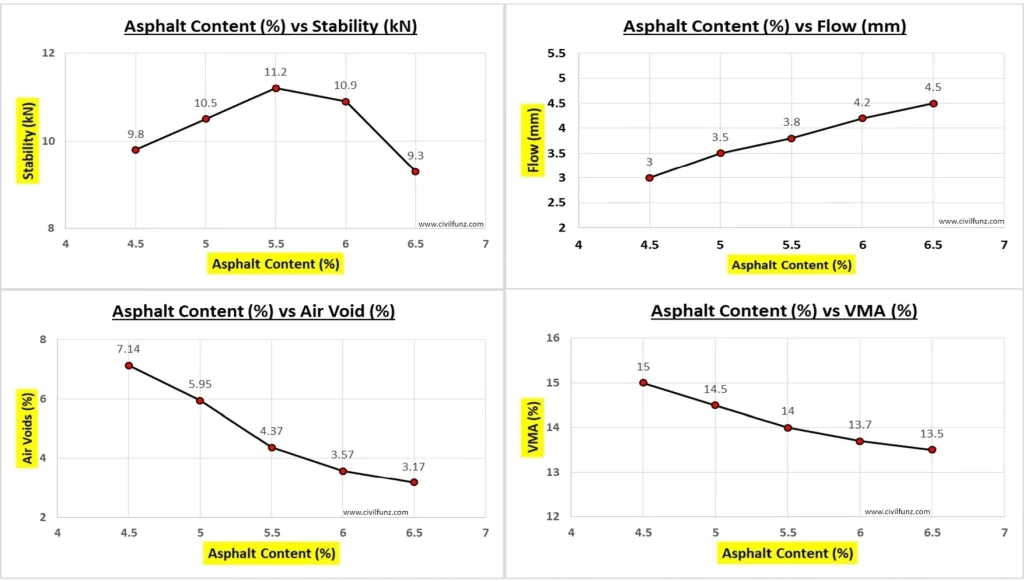

Asphalt, also known as bitumen, is one of the most widely used materials in pavement construction. It consists of aggregates (such as sand, gravel, and crushed stone) and a binder, typically bitumen, which is derived from petroleum.

(Asphalt Mix Design process)

- Properties: Asphalt pavements are popular due to their flexibility, smoothness, ease of construction, and ability to withstand heavy loads and harsh weather conditions. They are also relatively quick to repair, making them a preferred choice for high-traffic areas.

- Applications: Used for highways, urban roads, and airport runways.

- Types:

– Hot Mix Asphalt (HMA): Mixed and placed at high temperatures.

– Warm Mix Asphalt (WMA): Produced at lower temperatures, reducing energy consumption and emissions.

– Cold Mix Asphalt: Mixed and applied at ambient temperatures, suitable for low-traffic areas and repairs.

A.1.2. Portland Cement Concrete (PCC)

Concrete pavements are made from a mixture of cement, water, sand, and aggregates.

- Properties: Rigid, strong, and long-lasting. Resistant to heavy loads and weather conditions.

- Applications: Used for highways, airport runways, and urban roads with heavy traffic.

- Types :

– Jointed Plain Concrete Pavement (JPCP): Includes joints to control cracking.

– Jointed Reinforced Concrete Pavement (JRCP): Includes steel reinforcement to control cracking.

– Continuously Reinforced Concrete Pavement (CRCP): Includes continuous steel reinforcement, eliminating joints.

A.2. Base and Subbase Layer Materials

A.2.1. Crushed Stone or Gravel

- Properties: Provides strength and stability. Good load-bearing capacity and drainage properties.

- Applications: Used as a base or subbase layer under both asphalt and concrete pavements.

A.2.2. Stabilized Base/Subbase

- Properties: Enhanced strength and stability through the addition of stabilizing agents (e.g., cement, lime, bitumen).

- Applications: Used in areas with weak subgrades or high traffic loads.

A.3. Subgrade Materials

A.3.1. Natural Soil

- Properties: Forms the foundation for the pavement structure. Properties vary widely based on soil type and conditions.

- Applications: Must be appropriately prepared and compacted to provide a stable base for the pavement.

A.3.2. Improved Subgrade

- Properties: Enhanced strength and stability through treatment or stabilization (e.g., compaction, soil stabilization with lime or cement).

- Applications: Used in areas with weak or problematic soils

A.4. Modern Materials

A.4.1. Geosynthetics

Geosynthetics, such as geotextiles and geomembranes, are synthetic materials used to enhance pavement performance. They typically improve soil stabilization, drainage, and load distribution. By reinforcing the underlying soil and controlling moisture, geosynthetics can extend pavement lifespans and reduce maintenance needs.

A.4.2. Recycled Materials

The use of recycled materials in pavement construction is growing as sustainability becomes a key concern. Common examples include recycled asphalt pavement (RAP) and recycled concrete aggregate (RCA). These materials reduce the demand for virgin resources and can save costs while maintaining performance standards. Innovations like rubberized asphalt, which incorporates recycled rubber tires, are gaining traction for their enhanced durability and environmental benefits.

- Properties: Environmentally friendly and cost-effective. It can provide adequate strength and stability.

- Applications: Used as base or subbase layers. Common materials include recycled concrete aggregate (RCA) and reclaimed asphalt pavement (RAP

Selecting the appropriate pavement materials is crucial for balancing performance, cost, and sustainability. Understanding the properties and applications of different materials allows engineers to design pavements that meet specific requirements, ensuring durability and efficiency. In the following sections, we will explore the principles of pavement design, which guide the selection and application of these materials in creating robust and long-lasting paved surfaces.

B. Principles of Pavement Design

Pavement design involves selecting appropriate materials and structural designs to create a durable, safe roadway surface that can withstand traffic loads and environmental conditions. Here is an overview of the principles of pavement design

B.1. Structural Integrity

- Objective: Ensure the pavement can support expected traffic loads without excessive deformation or failure.

- Implementation: Use layers of materials with adequate strength and stiffness designed to distribute loads effectively.

B.2. Load Distribution

- Objective: Spread traffic loads over a broad area to reduce stress on the subgrade.

- Implementation: Design a multi-layer system (surface, base, and subbase) where each layer has specific properties to aid load distribution.

B.3. Durability

- Objective: Achieve a long service life with minimal maintenance.

- Implementation: Select materials that can withstand local weather conditions, traffic loads, and environmental stressors. Design for adequate drainage to prevent water damage.

B.4. Serviceability

- Objective: Maintain a smooth, safe, and functional road surface throughout its lifespan.

- Implementation: Design for minimal roughness and appropriate friction levels. Plan for periodic maintenance and rehabilitation

B.5. Economics

- Objective: Balance initial construction costs with long-term maintenance and rehabilitation costs.

- Implementation: Use cost-effective materials and construction techniques. Optimize the pavement design to minimize life-cycle costs.

In summary, the principles of pavement design are essential for developing infrastructures that support efficient transportation networks. By adhering to these principles and leveraging modern materials and technologies, we can build roads that are robust, cost-effective, and environmentally friendly. As we progress, continued advancements in pavement engineering will play a crucial role in addressing the evolving infrastructure development and maintenance challenges.

Keep Reading: Discover More Insights

- How to Calculate Bitumen Percentage in Hot Mix Asphalt: Methods Explained

- Gradation Curves: Importance in Construction and Step-by-Step Guide with Real-World Examples

- Ensuring Longevity: Materials, Drainage, and Environmental Compliance in Road Construction

- How to Calculate Concrete Mix Ratio: Simple Breakdown

- Road Construction 101: Key Steps Every New Engineer Should Know