Building roads is a challenging task, especially for engineers who are just beginning their careers. However, by understanding the key stages of road construction, you can approach your site visits with more confidence and a clear sense of direction.

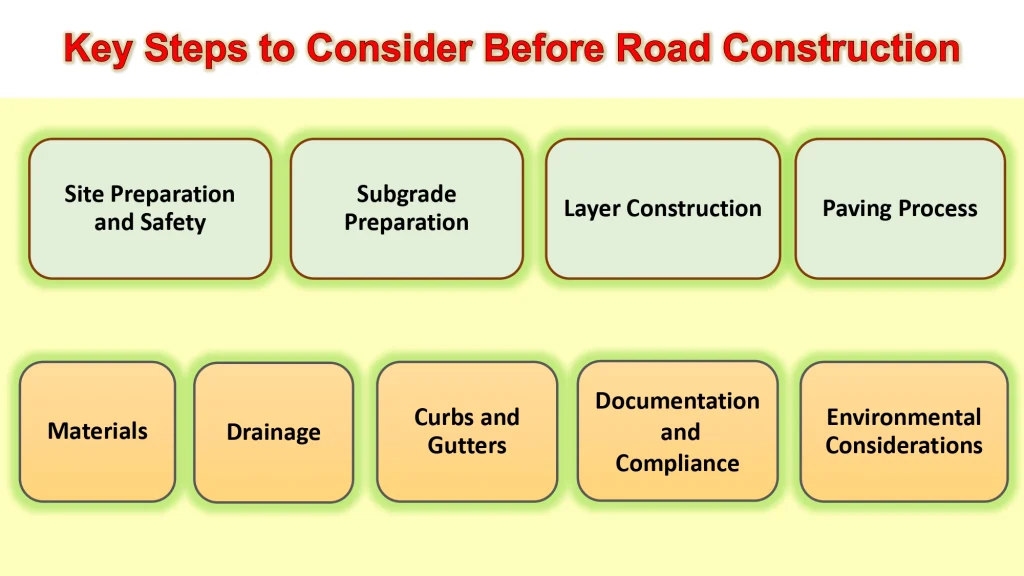

In this article, I will explain the key stages: Site Preparation, Subgrade Preparation, Layer Construction, and the Paving Process. Each stage requires careful planning and execution. By carefully studying this article, you’ll know exactly what to check and what questions to ask when you visit any road construction site.

Stay tuned for a follow-up article, where I will discuss other essential stages of road construction, such as Materials Selection, Drainage Systems, Curbs and Gutters, Documentation & Compliance, and Environmental Considerations—areas that are equally vital for the success and sustainability of any road construction project.

1. Site Preparation and Safety

Proper site preparation and adherence to safety protocols are essential steps in road construction to ensure a smooth, efficient, and safe project execution.

Here’s a brief overview of the key aspects:

1.1. Site Clearance

The purpose of site clearance is to create a clean and workable site by removing all obstacles, including vegetation, debris, and existing structures.

Actions:

– Clearing: Cut and remove trees, shrubs, and other vegetation.

– Grubbing: Remove roots, stumps, and other organic materials from the ground.

– Debris Removal: Clear away rocks, old pavement, and other debris to prepare the site for construction

1.2. Grading and Leveling

The purpose of Grading and Levelling is to achieve the desired slope and elevation for the roadbed to ensure proper drainage and structural integrity.

Actions:

– Excavation: Remove excess soil to achieve the desired grade.

– Filling: Add soil to low areas to reach the required level.

– Compaction: Compact the soil to provide a stable base for further construction.

1.3. Utility Relocation

The purpose of the Utility Relocation is to avoid interference and to ensure that existing utilities such as water lines, gas lines, and electrical cables do not obstruct construction activities.

Actions

– Identification: Locate and mark existing utilities.

– Coordination: Work with utility companies to relocate or adjust utilities as needed.

1.4. Safety Protocols

The purpose of safety protocols is to Protect Workers and the Public by ensuring the safety of all personnel on-site and the surrounding community.

Actions

– Personal Protective Equipment (PPE): Require all workers to wear appropriate PPE, such as hard hats, safety vests, gloves, and safety boots.

– Safety Signage: Place clear and visible signage around the site to warn of hazards and guide traffic.

– Training: Provide safety training to all workers, covering topics such as equipment operation, hazard recognition, and emergency procedures.

– Barriers and Fencing: Erect barriers and fencing to restrict access to hazardous areas and protect the public.

1.5. Traffic Management

The main purpose of Traffic Management is to Minimize Disruption by Managing the traffic flow around the construction site to ensure the safety of road users and workers.

Actions

– Detours and Signage: Set up detours and place signage to guide traffic safely around the construction zone.

– Flaggers: Use flaggers to direct traffic and ensure safe passage through or around the site.

– Temporary Roadways: Construct temporary roads if necessary to maintain access for vehicles and pedestrians.

Site preparation and safety are critical steps in road construction that involve clearing and grading the site, relocating utilities, implementing erosion control measures, and ensuring comprehensive safety protocols. Proper execution of these steps creates a stable foundation for construction activities and protects the safety of workers and the public

2. Subgrade Preparation

Subgrade preparation is a crucial step in road construction that ensures the stability and longevity of the roadway. The subgrade acts as the foundation for all subsequent layers, so it must be properly prepared to support the loads imposed by traffic and environmental conditions. Here’s a brief overview of the key aspects:

2.1. Evaluation and Testing

The purpose of Evaluation and Testing is to Determine Suitability by assessing the existing soil conditions to ensure the subgrade can provide adequate support.

Actions

– Soil Testing: Conduct tests such as the California Bearing Ratio (CBR), Proctor compaction tests, and Atterberg limits to evaluate soil properties.

– Moisture Content: Check the moisture content of the soil to determine if adjustments are needed for optimal compaction.

2.2. Clearing and Grubbing

The purpose of Clearing and Grubbing is to remove Obstacles by clearing the site of vegetation, debris, and organic materials that can affect the stability of the subgrade.

Actions

– Vegetation Removal: Cut and remove trees, shrubs, and grass..

– Grubbing: Remove roots, stumps, and other organic materials from the soil surface.

2.3. Excavation and Filling

Excavation and Filling are done to achieve the desired Grade by Shaping the terrain to the required elevation and slope

Actions

– Excavation: Remove excess soil to lower the subgrade to the desired level.

– Filling: Add soil to areas that are below the required level.

– Grading: Smooth and level the surface to achieve the specified grade and slope.

2.4. Compaction of Subgrade

Compaction is to increase Stability by Compacting the soil to improve its density and strength, reducing the risk of settlement and deformation.

Actions

– Equipment: Use rollers, compactors, and other machinery to compact the soil.

– Layer-by-Layer: Compact the soil in thin layers (lifts) to ensure uniform density and avoid pockets of loose material.

– Moisture Control: Adjust the moisture content of the soil to achieve optimal compaction. Add water to dry soil or aerate wet soil as needed.

2.5. Stabilization (if required)

Stabilization is to enhance Soil Properties by improving the strength and durability of weak or unstable soils.

Actions

– Additives: Incorporate materials such as lime, cement, or fly ash into the soil to enhance its properties.

– Mixing: Thoroughly mix the additives with the soil to ensure even distribution.

– Compaction: Compact the stabilized soil to achieve the required density.

2.6. Quality Control of Subgrade

The purpose of the Quality Control is to ensure compliance by verifying that the subgrade meets the specified requirements for compaction, moisture content, and stability

Actions

– Field Testing: Conduct in-situ tests such as nuclear density tests and moisture content checks to confirm compliance.

– Inspection: Regularly inspect the subgrade during preparation to identify and address any issues promptly.

Subgrade preparation involves evaluating and testing soil properties, clearing and grubbing the site, performing excavation and filling to achieve the desired grade, and compacting the soil to enhance its stability and strength. If necessary, soil stabilization techniques are employed to improve weak soils. Quality control measures ensure the subgrade meets all specifications, providing a solid foundation for the road construction.

3. Layer Construction

Layer construction is a critical aspect of road construction, involving the creation of multiple layers that provide a stable and durable roadway. Each layer has a specific function and must be constructed with precision to ensure the overall integrity and performance of the road. Here’s a brief overview of the key layers:

3.1. Subgrade Preparation

The purpose of Subgrade is to provide foundation and stability:

– Foundation: Acts as the foundation of the road, providing support for all upper layers.

– Stability: Ensures a stable base, preventing settlement and deformation.

Action:

– Compaction: Compact the subgrade to achieve the desired density and strength.

– Moisture Control: Ensure proper moisture content to facilitate compaction and prevent future instability.

3.2. Sub-base Layer

The purpose of the Sub-base Layer is to provide drainage and load distribution

– Load Distribution: Distributes traffic loads to the subgrade, reducing stress on the underlying soil.

– Drainage: Provides a pathway for water to drain away from the pavement structure.

Materials:

– Granular Materials: Commonly made of crushed stone, gravel, or sand.

Action:

– Placement: Spread the sub-base material evenly.

– Compaction: Compact the sub-base to achieve the specified density.

3.3. Base Course Layer

The purpose of Base Course Layer is to provide strength and support

– Strength: Provides additional strength and load-bearing capacity

– Support: Supports the asphalt layer and helps prevent deformation.

Materials:

– Higher Quality Aggregates: Often made from crushed stone or crushed concrete.

Action:

– Placement: Lay the base course material evenly over the sub-base.

– Compaction: Compact the base course thoroughly to achieve the required density and smoothness.

3.4. Asphalt Paving

The purpose of Asphalt is to provide a durable surface layer along with load distribution capacity:

– Surface Layer: Provides a smooth, durable, and weather-resistant surface for vehicles

– Load Distribution: Helps distribute vehicle loads to the underlying layers.

Materials:

– Hot Mix Asphalt (HMA): A mixture of aggregates and bitumen.

Action:

– Paver Setup: Set up the asphalt paver machine at the site.

– Asphalt Placement: Place the asphalt mix uniformly, ensuring the correct thickness.

– Compaction: Perform initial, intermediate, and final rolling to compact the asphalt while it is still hot.

3.5. Compaction of Different Layers

Compaction is essential to provide density and smoothness.

– Density: Achieve the desired density to ensure strength and durability.

– Smoothness: Ensure a smooth, even surface for optimal driving conditions.

Equipment:

– Rollers: Use steel-wheeled rollers, pneumatic tire rollers, and vibrating rollers for compaction

Action:

– Initial Rolling: Perform initial rolling to remove air voids.

– Intermediate Rolling: Use pneumatic tire rollers for further compaction.

– Final Rolling: Use steel-wheeled rollers to achieve a smooth surface.

Quality control during layer construction is crucial for compliance and performance in road construction. It ensures that each layer meets the project’s specifications and standards. This involves various tests:

– Compaction Testing: Conducted to verify proper density and compaction.

– Material Testing: Ensures the quality of materials used in each layer.

The process includes preparing the subgrade, placing and compacting the sub-base and base course layers, and paving with hot mix asphalt. Proper construction and compaction of each layer are vital for the road’s stability, durability, and performance, ultimately ensuring the pavement structure adheres to all required specifications and standards.

4. Paving Process

The paving process is a critical phase in road construction, involving the placement and compaction of asphalt to create a smooth, durable, and long-lasting surface. Here’s a brief overview of the key steps involved:

4.1. Preparation

It is required to ensure Readiness by preparing the site and equipment for asphalt paving.

Actions:

– Clean Surface: Ensure the base layer is clean, dry, and free of debris.

– Prime Coat: Apply a prime coat to the base layer to enhance bonding with the asphalt.

4.2. Hot Mix Asphalt (HMA) Production

The purpose is to produce the asphalt mix with the required properties.

(Read More about Asphalt Mix Design)

Actions:

– Mixing: Combine aggregates and bitumen at a hot mix asphalt plant at high temperatures.

– Quality Control: Test the mix to ensure it meets design specifications.

4.3. Transportation

The purpose is to transport the HMA to the construction site while maintaining the required temperature

Actions:

– Insulated Trucks: Use insulated trucks to transport the hot mix asphalt to the site to prevent cooling.

4.4. Asphalt Placement

The purpose is to place the asphalt mix on the prepared base layer uniformly.

Actions:

– Paver Machine: Use an asphalt paver to lay the mix evenly

– Thickness Control: Monitor and control the thickness of the laid asphalt to meet specifications.

4.5. Compaction during Paving

The purpose is to achieve Density by Compacting the asphalt to increase its density and strength.

Actions:

– Initial Rolling: Perform initial compaction with a steel-wheeled roller to remove air voids

– Intermediate Rolling: Use a pneumatic tire roller for further compaction and better aggregate interlock.

– Final Rolling: Conduct final rolling with a steel-wheeled roller to achieve smoothness and the desired density while the asphalt is still hot.

4.6. Joints

The goal is to ensure continuity, and to prevent water infiltration and ensure a smooth transition between sections.

Actions:

– Longitudinal Joints: Compact joints between adjacent lanes properly.

– Transverse Joints: Ensure smooth and well-compacted transitions between new and old sections of asphalt.

4.7. Surface Finishing

It is done to achieve smoothness by Ensuring the asphalt surface is smooth and even.

Actions:

– Surface Texture: Avoid segregation, ruts, and other imperfections.

– Edge Finishing: Smooth and finish the edges of the asphalt pavement.

4.8. Quality Control

The goal is to ensure compliance to verify that the asphalt paving meets all design specifications and quality standards.

Actions:

– Temperature Checks: Ensure the asphalt is laid and compacted at the correct temperatures.

– Compaction Testing: Conduct density tests to ensure proper compaction.

– Smoothness Testing: Use straightedges or laser profilers to check for smoothness.

4.9. Curing and Cooling

Curing is done to allow the asphalt to cool and harden before opening to traffic.

Actions:

– Cooling Period: Let the asphalt cool to ambient temperature.

4.10. Road Markings and Signage

Road Markings and signages are very important to make a safer road for the users.

Actions:

– Markings: Apply road markings such as lane stripes and crosswalks using specialized paint or thermoplastic materials.

– Signs: Install required traffic signs according to the project plan.

The paving process in road construction involves preparing the site, producing and transporting hot mix asphalt, placing and compacting the asphalt, and finishing the surface. Proper execution of each step ensures a smooth, durable, and high-quality road surface that meets all specifications and standards.

Constructing a road is a complex endeavor, particularly for fresh engineers who may encounter various challenges due to their inexperience. This article has walked you through the essential stages of site preparation, subgrade preparation, layer construction, and the paving process—each a critical component in building a durable and safe roadway. By understanding and applying the insights shared here, you’ll be better prepared to address the common issues that arise during road construction, paving the way for successful project outcomes. In the upcoming article, I will cover the next set of important topics: Materials Selection, Drainage, Curbs and Gutters, Documentation and Compliance, and Environmental Considerations. Together, these insights will provide a comprehensive understanding that will greatly assist you in your journey as an engineer in road construction.