The Marshall Mix Design method is widely used for designing asphalt pavements. Bruce Marshall developed it in the late 1930s and refined it over the years. The Marshall Mix Design aims to determine the optimum asphalt content for a given aggregate blend to achieve a durable and stable mix.

Here’s a detailed step-by-step explanation of the Marshall Mix Design process.

Contents

Marshall Mix Design Method step-by-step using a hypothetical Example

Suppose we are designing an asphalt mix for a road project. We have selected the following materials:

Aggregates: A blend of coarse aggregate, fine aggregate, and mineral filler.

Asphalt Binder: PG 64-221.

Step 1: Selection of Materials

Aggregates:

– Ensure the aggregates meet the required specifications for gradation and properties.

Asphalt Binder:

– Select the appropriate binder based on the project’s climatic conditions and traffic loads.

Step 2: Preparation of Specimens

Aggregate Blending:

– Blend the aggregates to achieve a specific gradation. For example, we want a gradation curve that meets the middle of the specification limits.

Batching:

– Prepare five different batches of aggregates, each with different asphalt binder content: 4.5%, 5.0%, 5.5%, 6.0%, and 6.5%.

Mixing:

– Heat the aggregates and asphalt binder separately to the mixing temperature (typically around 150°C for both).

– Mix the heated aggregates and binder thoroughly to coat all aggregate particles.

Compaction:

– Compact each mixture in a Marshall mold with 75 blows per side using a Marshall compactor.

Step 3: Testing of Specimens

Density and Void Analysis:

– Bulk Specific Gravity(Gmb): Measure the bulk specific gravity of the compacted specimens.

– Maximum Theoretical Specific Gravity (Gmm): Determine this using a loose mix sample.

– Air Voids (Va): Va = {1- (Gmb/Gmm ) } X 100

– Voids in Mineral Aggregate (VMA): VMA = { (Vtotal– Vbinder) / Vtotal } X 100

– Voids Filled with Asphalt (VFA): VFA = { (VMA- Va) / VMA } X 100

Stability and Flow Test:

– Place the specimen in a Marshall Stability testing machine.

– Load the specimen until failure to measure stability (in kN or lbs)

– Record the flow value (deformation at failure in mm or inches)

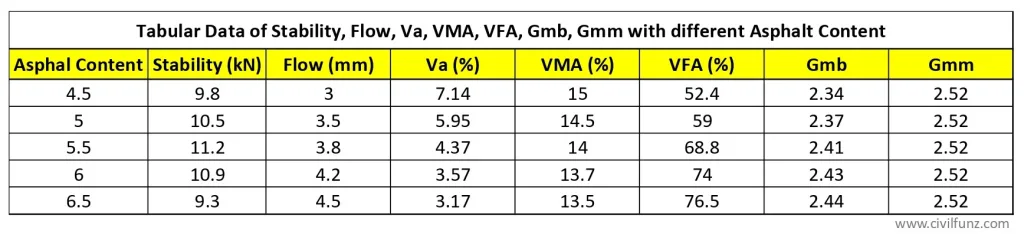

Data Collection:

Step 4: Determination of Optimum Asphalt Content

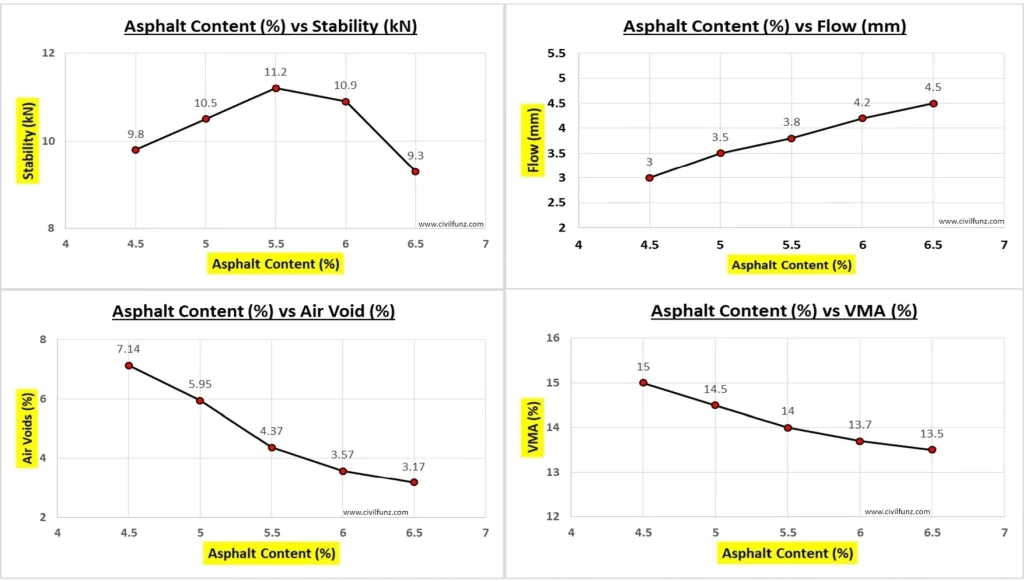

Plotting Results:

– Plot the test results of Asphalt Content for Stability, Flow, Air Voids, VMA, and VFA.

Analysis:

- Stability: Look for the peak value (11.2 kN at 5.5% asphalt).

- Flow: Should be within the specified range (typical 2-4 mm).

- Air Voids: Aim for 3-5% for durable pavement (4.37% at 5.5% asphalt).

- VMA: Should meet minimum requirement (usually 13-15%).

- VFA: Should be within 65-75% (68.8% at 5.5% asphalt).

The optimum asphalt content is determined by balancing these factors.

In this case, 5.5% asphalt content is optimal.

Step 5: Verification and Adjustments

Verification:

– Prepare additional specimens at 5.5% asphalt content.

– Test to verify that all properties meet the specifications.

Adjustments:

– If any property is out of range, adjust the mix design accordingly (e.g., tweak aggregate gradation).

Step 6: Finalize Design

Design Documentation:

– Document the final mix design, including the selected asphalt content, aggregate gradation, and all test results.

– Prepare detailed construction specifications.

Implementation and Monitoring:

– Implement the mix design in the field.

– Monitor the performance of the pavement to ensure it meets the expected performance criteria.

Objectives of Marshall Mix Design

- Stability: Ensure the mix can withstand traffic loads without excessive deformation.

- Durability: Provide resistance to weathering and disintegration.

- Flexibility: Maintain sufficient flexibility to avoid cracking under repeated traffic loads.

- Workability: Ensure the mix is easy to place and compact.

- Economy: Achieve the desired properties at the lowest possible cost.

Advantages of Marshall Mix Design

- Simplicity and Practicality:

The Marshall method is relatively simple to perform and does not require highly sophisticated equipment, making it accessible for many laboratories and agencies. - Cost-Effective:

The method is cost-effective in terms of both equipment and time, providing reliable results without significant investment. - Well-Established:

It is a well-established method with a long history of successful application, ensuring familiarity and confidence among practitioners. - Standardized Procedure:

The method follows standardized procedures, ensuring consistency and repeatability in the design process. - Performance Indicators:

Provides key performance indicators such as stability, flow, air voids, VMA, and VFA, which are essential for assessing the quality of the asphalt mix.

Disadvantages of Marshall Mix Design

- Empirical Nature:

Being primarily empirical, the method may not fully account for the mechanistic behavior of materials under varying conditions. - Limited to Certain Traffic and Climatic Conditions:

The method may not be as effective for very heavy traffic loads or extreme climatic conditions without additional adjustments or calibrations.. - Lack of Consideration for Modern Materials

It may not fully accommodate the properties of newer, modified asphalt binders and aggregate types used in contemporary pavements. - Simplified Compaction Process:

The compaction process in the lab may not accurately replicate field compaction, potentially leading to discrepancies between lab and field performance.

The Marshall Mix Design method involves preparing and testing multiple asphalt-aggregate mixtures to determine the optimum asphalt content that balances stability, durability, and workability. Systematically analyzing and adjusting the mix properties ensures the pavement will perform well under traffic and environmental conditions. While the Marshall method is widely used, it’s also important to be aware of other mix design methods, such as the Superpave (Superior Performing Asphalt Pavements) system, which incorporates more comprehensive material testing and analysis to accommodate a wider range of traffic and climate conditions, and the Hveem method, which focuses on the compaction and density of the mix. Understanding these alternatives can provide more flexibility and options for achieving the best possible pavement performance.

Footnotes:

- PG 64-22: It refers to a specific grade of asphalt binder used in pavement construction, particularly for roads and highways. The “PG” stands for “Performance Grade,” and the numbers following it indicate the temperature range within which the binder is designed to perform effectively.

PG 64-22 asphalt binder is designed to perform well in regions where the pavement temperature ranges from as high as 64°C to as low as -22°C ↩︎

Keep Reading: Discover More Insights

Recent Posts

- How to Calculate Bitumen Percentage in Hot Mix Asphalt: Methods Explained

- Gradation Curves: Importance in Construction and Step-by-Step Guide with Real-World Examples

- Ensuring Longevity: Materials, Drainage, and Environmental Compliance in Road Construction

- How to Calculate Concrete Mix Ratio: Simple Breakdown

- Road Construction 101: Key Steps Every New Engineer Should Know