Determining the bitumen (asphalt binder) percentage in Hot Mix Asphalt (HMA) is crucial for ensuring that the asphalt mix meets the specified design criteria for durability, strength, and performance. Accurate determination of bitumen content is not just a routine task—it is a critical step in the mix design process. Mix design ensures that the right proportions of aggregates, binder, and additives are selected to achieve optimal performance under varying traffic loads and environmental conditions. Methods like the Marshall Mix Design and Superpave Mix Design play a key role in creating asphalt mixes that provide the desired balance between flexibility and rigidity. The bitumen content in HMA can be determined using several methods, including the Ignition Method, Solvent Extraction Method, Centrifuge Extraction Method, Nuclear Asphalt Content Gauge, and Microwave Oven Method.

Different Methods for Calculating Bitumen Percentage

1. Ignition Method: Quick and Accurate

This is a widely used method because it is relatively quick and accurate.

Procedure:

Sample Preparation: A representative sample of HMA is obtained and weighed.

Heating: The sample is placed in an ignition oven, which is preheated to a specific temperature (usually around 538°C or 1000°F).

Burning Off the Bitumen: The oven burns off the bitumen binder, leaving behind the aggregate.

Weight Measurement: After complete combustion, the sample is allowed to cool, and the remaining aggregate is weighed.

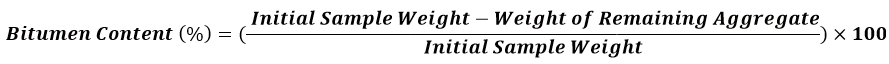

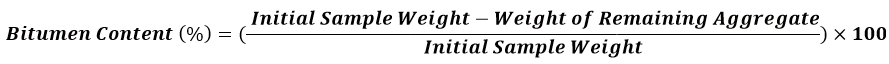

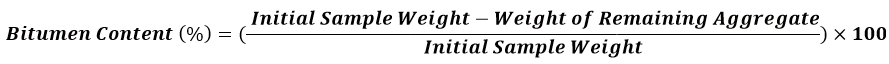

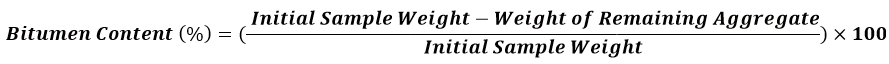

Bitumen Content Calculation: The bitumen content is calculated based on the weight difference before and after ignition. The weight of the aggregate is subtracted from the original sample weight to determine the weight of the bitumen.

2. Solvent Extraction Method (AASHTO T 164): Precision at Its Best

Solvent extraction, or liquid-liquid extraction, is a widely used separation technique in which a liquid solvent is utilized to selectively extract a specific compound from a solid or liquid mixture.

Procedure:

Sample Preparation: A representative sample of HMA is obtained and weighed.

Solvent Addition: The sample is placed in an extraction apparatus, and a solvent (such as trichloroethylene or methylene chloride) is added to dissolve the bitumen.

Extraction Process: The apparatus agitates the mixture, separating the bitumen from the aggregate.

Separation and Filtration: The dissolved bitumen solution is filtered out, leaving the aggregate behind. The solvent is then evaporated or distilled to recover the bitumen.

Weight Measurement: The aggregate is dried and weighed. The bitumen content is determined by the weight difference using the formula given below.

3. Centrifuge Extraction Method : Speed Meets Solvent

This method also uses a solvent but separates the bitumen through centrifugation.

Procedure:

Sample Preparation: A representative sample of HMA is obtained and weighed.

Solvent Addition: The sample is placed in a centrifuge bowl, and a solvent is added.

Centrifugation: The mixture is centrifuged to separate the bitumen-solvent solution from the aggregate.

Filtration and Drying: The bitumen-solvent solution is filtered, and the aggregate is dried and weighed.

Weight Measurement: The aggregate is dried and weighed. The bitumen content is calculated by the weight difference using the formula mentioned below.

4. Microwave Oven Method: Rapid Testing

A rapid method similar to the ignition method but using a microwave oven.

Procedure:

Sample Preparation: A representative sample of HMA is obtained and weighed

Heating: The sample is placed in a microwave oven, and special containers designed for this purpose are used.

Burning Off the Bitumen: The microwave oven heats the sample to burn off the bitumen.

Weight Measurement: After cooling, the remaining aggregate is weighed.

Bitumen Content Calculation: The bitumen content is calculated based on the weight difference using the following formula

5. Nuclear Asphalt Content Gauge: Non-Destructive Testing

This method uses a nuclear gauge to determine the bitumen content non-destructively.

Procedure:

Calibration: The gauge is calibrated using known HMA samples

Measurement: The gauge is placed on the HMA sample, and it measures the hydrogen content, which correlates to the bitumen content.

Calculation: The bitumen content is read directly from the gauge based on the calibration.

The choice of method depends on the available equipment, accuracy required, and specific project requirements. The ignition method is highly popular for its balance of speed and accuracy, while solvent extraction methods are known for their precision. Each method has its advantages and limitations, and selecting the appropriate one ensures accurate determination of the bitumen content in HMA. This accuracy is critical as it directly influences the performance of the mix design. Properly designed asphalt mixes enhance the pavement’s durability, strength, and resistance to deformation, ensuring a long service life for roadways and other structures